Welcome to my electricalheatpump.com blog, where i am trying to put all my knowledge about heat pump in one place, which can be very useful foe the readers and followers to get all the stuff in a single blog, i try to put my best efforts possible to bring all here, and todays post is all about the Principles behind the heat pump, working of the heat pump in detail and the major components involved in heat pump. read through and share your feedback on comments.

Industrial heat pumps are emerging as pivotal technologies in the pursuit of enhanced energy efficiency and sustainability across various sectors. These sophisticated systems offer a compelling alternative to traditional heating and cooling methods by efficiently transferring thermal energy rather than generating it directly. Their fundamental principle revolves around the ability to absorb thermal energy from a lower-temperature source and elevate it to a higher, more useful temperature, thereby providing both heating and cooling capabilities for industrial processes and building climate control. As the global focus intensifies on reducing carbon emissions and transitioning towards cleaner energy sources, industrial heat pumps are gaining significant traction due to their potential to utilize waste heat and integrate seamlessly with renewable energy supplies. This capability not only contributes to environmental sustainability but also presents opportunities for substantial cost savings and the development of innovative business models centered around energy recovery and reuse.

The Core Principle: The Magic of Heat Transfer

At the heart of industrial heat pump operation lies a set of fundamental thermodynamic principles, mirroring those found in familiar technologies like refrigerators and air conditioners. However, the primary objective of a heat pump is often the delivery of heat, rather than just cooling. The cornerstone of their functionality is the refrigeration cycle, a process that allows for the efficient movement of heat from one location to another. While the natural tendency of heat is to flow from warmer to cooler areas, heat pumps employ mechanical work to reverse this flow, effectively “pumping” heat from a cold source to a warmer destination

A critical physical property underpinning this process is the relationship between the boiling point of a fluid and its pressure. By reducing the pressure on a fluid, its boiling point decreases, allowing it to evaporate at lower temperatures. Conversely, increasing the pressure raises the boiling point, enabling condensation at higher temperatures. This principle is central to how heat pumps can extract heat from relatively cold sources and release it at significantly higher temperatures.

To understand the theoretical limits of this heat transfer, the concept of the Carnot cycle is often invoked. This idealized thermodynamic cycle represents the most efficient way to convert heat into work, or, in reverse, to move heat between two temperature reservoirs. Although real-world heat pumps cannot achieve the perfect efficiency of a Carnot cycle due to inherent irreversibility’s, it serves as a crucial benchmark for evaluating and improving their performance. The second law of thermodynamics dictates that transferring heat from a colder to a hotter region necessitates an input of external work. Industrial heat pumps adhere to this law by utilizing energy, typically in the form of electricity, to drive the refrigeration cycle and facilitate this seemingly counter-intuitive heat transfer. The efficiency of this process is intricately linked to the magnitude of the temperature difference the heat pump needs to overcome; smaller temperature differentials generally result in higher efficiency.

How Industrial Heat Pumps Work: A Step-by-Step Guide

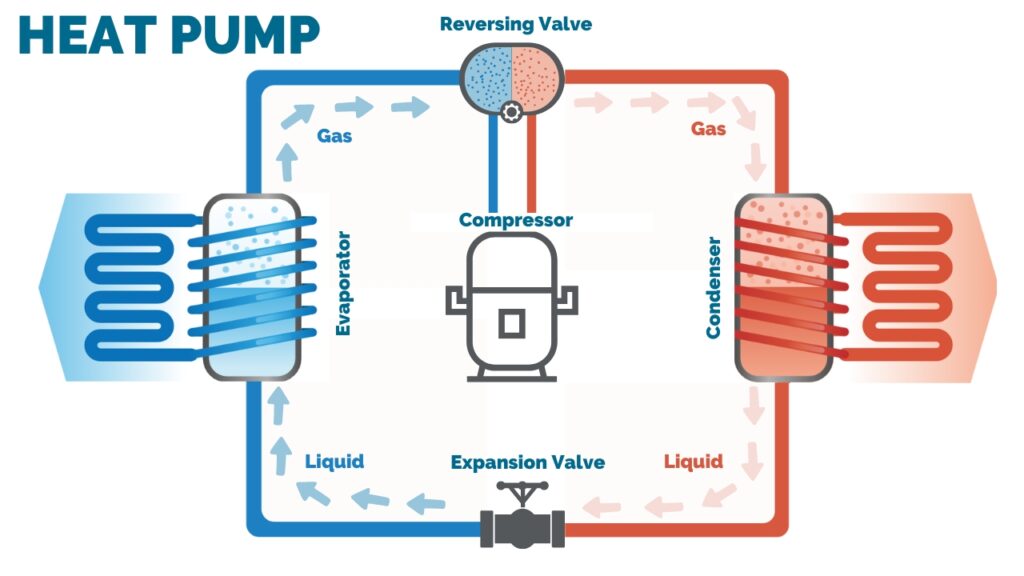

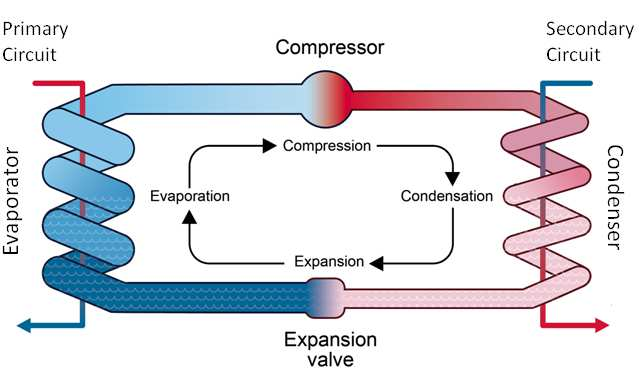

The operation of a typical industrial heat pump relies on the vapor-compression refrigeration cycle, which consists of four key stages executed in a closed loop

1. Evaporation:

The cycle commences in the evaporator, a heat exchanger where a low-pressure, low-temperature liquid refrigerant absorbs heat from a low-temperature source. This heat source can vary widely depending on the application, including waste heat generated by industrial processes, ambient air, geothermal energy, or water from rivers or lakes. As the refrigerant absorbs this heat, its temperature rises, causing it to vaporize and transform into a low-pressure, low-temperature gas.

2. Compression

The gaseous refrigerant then flows into the compressor, a critical component that increases both its pressure and temperature. This compression process converts the low-pressure gas into a high-pressure, high-temperature superheated gas.

The type of compressor used can vary based on the specific demands of the industrial application, with common types including reciprocating, scroll, rotary, and screw compressors. Industrial systems often employ larger and more robust compressors to handle the required pressure ratios and flow rates. The energy required to drive the compressor is typically electrical, but can also be supplied by mechanical sources such as steam turbines or combustion engines

3. Condensation

The high-pressure, high-temperature refrigerant gas then enters the condenser, another heat exchanger. Here, it releases the heat it absorbed in the evaporator, along with the energy added during compression, to a higher-temperature sink. This heat sink could be an industrial process requiring heating, a building’s heating system, or water intended for various uses. As the refrigerant releases its heat, it cools down and condenses back into a high-pressure liquid, albeit at a moderate temperature.

4. Expansion

Finally, the high-pressure liquid refrigerant flows through an expansion device, such as an expansion valve or a throttle valve. This device drastically reduces the pressure and temperature of the refrigerant, creating a low-pressure, low-temperature mixture of liquid and vapor. This low-temperature refrigerant is now ready to return to the evaporator and begin the cycle anew.

For industrial applications that require both heating and cooling, some heat pump systems are equipped with a reversing valve. This valve allows the roles of the condenser and evaporator to be switched, effectively reversing the direction of heat flow. In heating mode, heat is drawn from the outside (or a waste heat source) and transferred indoors, while in cooling mode, heat is extracted from the indoor space and expelled outdoors.

The overall efficiency of this cycle is significantly influenced by the temperature difference between the heat source and the heat sink. Utilizing waste heat sources with higher initial temperatures can substantially enhance the performance of industrial heat pumps by reducing the required temperature lift.

Meet the Key Players: Main Components Explained

The efficient operation of an industrial heat pump relies on the coordinated function of several key components:

- Evaporator: This heat exchanger acts as the point where the low-pressure liquid refrigerant absorbs heat from the low-temperature source. The source of this heat can be incredibly diverse, ranging from waste heat emanating from various industrial processes to naturally available sources like ambient air, geothermal reserves, or water bodies such as rivers and lakes. To maximize the heat transfer surface area and efficiency, the evaporator typically features a network of coils with attached fins.

- Compressor: Often considered the heart of the heat pump system, the compressor’s primary role is to take the low-pressure, low-temperature refrigerant gas from the evaporator and significantly increase its pressure and temperature. This process transforms the refrigerant into a high-pressure, high-temperature superheated gas, ready to release its energy in the condenser. Industrial heat pumps employ various types of compressors, including reciprocating, scroll, rotary, and screw types, with the selection depending on the specific application’s size and the required pressure levels. Given the demands of industrial settings, these systems often utilize larger and more robust compressors compared to residential or commercial units. The power to drive these compressors is predominantly supplied by electricity, although mechanical drives powered by steam turbines or combustion engines can also be used in certain scenarios.

- Condenser: Functioning as another crucial heat exchanger, the condenser is where the high-pressure, high-temperature refrigerant gas releases the heat it carries to a higher-temperature sink. This heat sink can be an industrial process that requires heating, a building’s central heating system, or water intended for various industrial or domestic uses. Similar to the evaporator, the condenser often incorporates a design featuring coils and fins to facilitate efficient heat exchange between the refrigerant and the heat sink medium.

- Expansion Valve (or Expansion Device): Located downstream of the condenser, the expansion valve plays a vital role in reducing the pressure and temperature of the liquid refrigerant. This significant pressure drop causes a portion of the refrigerant to undergo a rapid phase change, flashing into a low-temperature, low-pressure mixture of liquid and vapor. This prepares the refrigerant to absorb more heat in the evaporator, thus restarting the cycle. Various types of expansion devices are used in industrial heat pumps, including fixed orifices, thermostatic expansion valves (TXV), and the more advanced electronic expansion valves (EEV), each offering different levels of control over the refrigerant flow rate and pressure reduction.

The careful selection and appropriate sizing of each of these components are paramount to achieving optimal performance and efficiency in an industrial heat pump system. For instance, the efficiency and pressure ratio capabilities of the compressor directly dictate the maximum temperature lift that can be achieved and the overall energy consumption of the system. Similarly, the effectiveness of the heat exchangers in both the evaporator and the condenser determines the rate at which heat can be transferred between the refrigerant and the respective heat source and sink. Advancements in the design and materials used for these components are continuously driving improvements in the performance and expanding the range of applications for industrial heat pump technology

Industrial heat pumps represent a sophisticated and increasingly vital technology for enhancing energy efficiency and promoting sustainability across a wide spectrum of industrial applications. By understanding their fundamental thermodynamic principles, the step-by-step operation of their refrigeration cycle, and the crucial roles of their main components, industry professionals can better appreciate the significant benefits these systems offer. From their ability to efficiently upgrade waste heat to their potential for substantial reductions in greenhouse gas emissions and operating costs, industrial heat pumps are poised to play a pivotal role in achieving global decarbonization targets and fostering a more sustainable industrial future. As technology continues to advance and the economic landscape shifts, exploring the integration of industrial heat pumps into existing and new industrial operations presents a compelling opportunity to unlock significant efficiencies and contribute to a greener planet

Its pretty big read, I have tried to cut short it as possible as i can, but i wanted to keep it as simple as possible and also wanted more detailed.

Hope you have read it completely and it worth the time you spend on reading it.

please share your feedbacks and questions on this in the comments, will be very much happy to reply on it.

Will be making post on various topics on different types of heatpump, different cycle in the process, Benefits of heat pump in industries and application on each industries.